The global automotive industry is undergoing a transformative shift driven by electrification,智能化 (intelligence), and connectivity. At the heart of this evolution lies the automotive wiring harness connectors that power vehicle systems—from powertrains to infotainment. As technology advances, the demand for reliable, compact, and versatile connectors continues to rise, making 14-pin automotive connector solutions like the DJ7142-2.2-11 increasingly critical. Let’s explore the key trends reshaping the automotive connector landscape and why this 14-pin solution is at the forefront.

1. Miniaturization: Space-Efficient Connectivity for Modern Vehicles

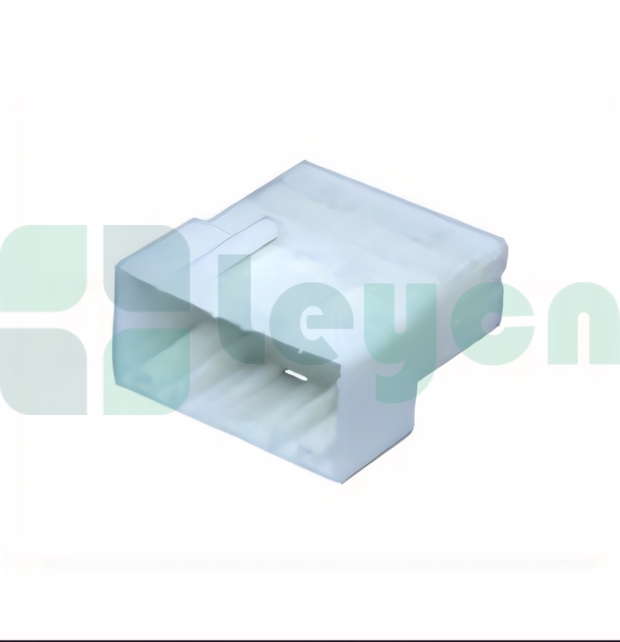

With vehicle engines shrinking, battery compartments consolidating, and new features like ADAS (Advanced Driver Assistance Systems) demanding more sensors, automotive designers are prioritizing automotive electrical connectors that maximize functionality in limited spaces. The DJ7142-2.2-11, a 14-pin connector, exemplifies this trend: its compact 2.2mm pitch and modular design allow for dense wiring layouts without compromising performance, ideal for both traditional ICE (Internal Combustion Engine) vehicles and EVs.

DJ7142-2.2-11

2. EV Integration: Power and Signal in Harmony

Electric vehicles (EVs) require connectors that handle high voltage, data transfer, and thermal stress simultaneously. The 14-pin configuration of the DJ7142-2.2-11 supports dual roles: power distribution for battery packs and communication for charging stations or in-vehicle diagnostics. This versatility makes it a go-to choice for manufacturers integrating multiple EV subsystems, reducing complexity and ensuring compliance with safety standards.

3. Smart Connectivity: Enabling the Connected Car

Today’s vehicles are becoming rolling data hubs, with infotainment, telematics, and V2X (Vehicle-to-Everything) systems relying on seamless signal transmission. 14-pin automotive connector solutions like the DJ7142-2.2-11 support the multi-signal routing needed for sensors, cameras, and infotainment modules. Its robust pin configuration ensures stable data flow, critical for real-time ADAS decision-making and over-the-air updates.

4. Durability and Environmental Resilience

Automotive connectors must endure extreme conditions: temperature fluctuations, road vibration, and exposure to moisture or chemicals. The DJ7142-2.2-11 is engineered with durable materials and a secure locking mechanism, ensuring long-term reliability even in harsh environments. This resilience is why it’s a trusted general-purpose automotive connector across a wide range of vehicle models, from passenger cars to light commercial vehicles.

5. Cost-Effective General-Purpose Solutions

For manufacturers, reducing component complexity and inventory costs is key. The DJ7142-2.2-11’s universal fit across general-purpose automotive connectors simplifies procurement, as it serves as a standard solution for multiple vehicle platforms. This lowers production lead times while maintaining quality—a win-win for both OEMs and aftermarket suppliers.

Conclusion

As the automotive industry races toward a future of EVs and smart mobility, connectors like the DJ7142-2.2-11 are not just components—they’re enablers. By balancing miniaturization, durability, and versatility, 14-pin solutions are driving innovation in connectivity, power management, and vehicle efficiency. For businesses seeking reliable, future-proof automotive wiring harness connectors, the DJ7142-2.2-11 stands as a prime example of how adaptability and performance intersect in modern automotive design.

![2024 Automotive Connector Trends: How 14-Pin Solutions Like [[DJ7142-2.2-11]] Are Shaping the Industry](https://www.leycn.uk/wp-content/uploads/2025/11/2024-automotive-connector-trends-how-14-pin-soluti-1763496081-L1lEYw-1024x1024.jpg)