As the automotive industry undergoes rapid transformation driven by electrification,智能化 (intelligence), and connectivity, the role of 汽车线束连接器 (automotive wiring harness connectors) has become increasingly critical. Among these components, pin sockets like the HD1532-0.7-31 play a pivotal role in ensuring reliable electrical and data transmission across diverse vehicle systems. Let’s explore how this specialized connector aligns with 2024 industry trends and meets the demands of modern automotive engineering.

1. Electrification: Powering the EV Revolution

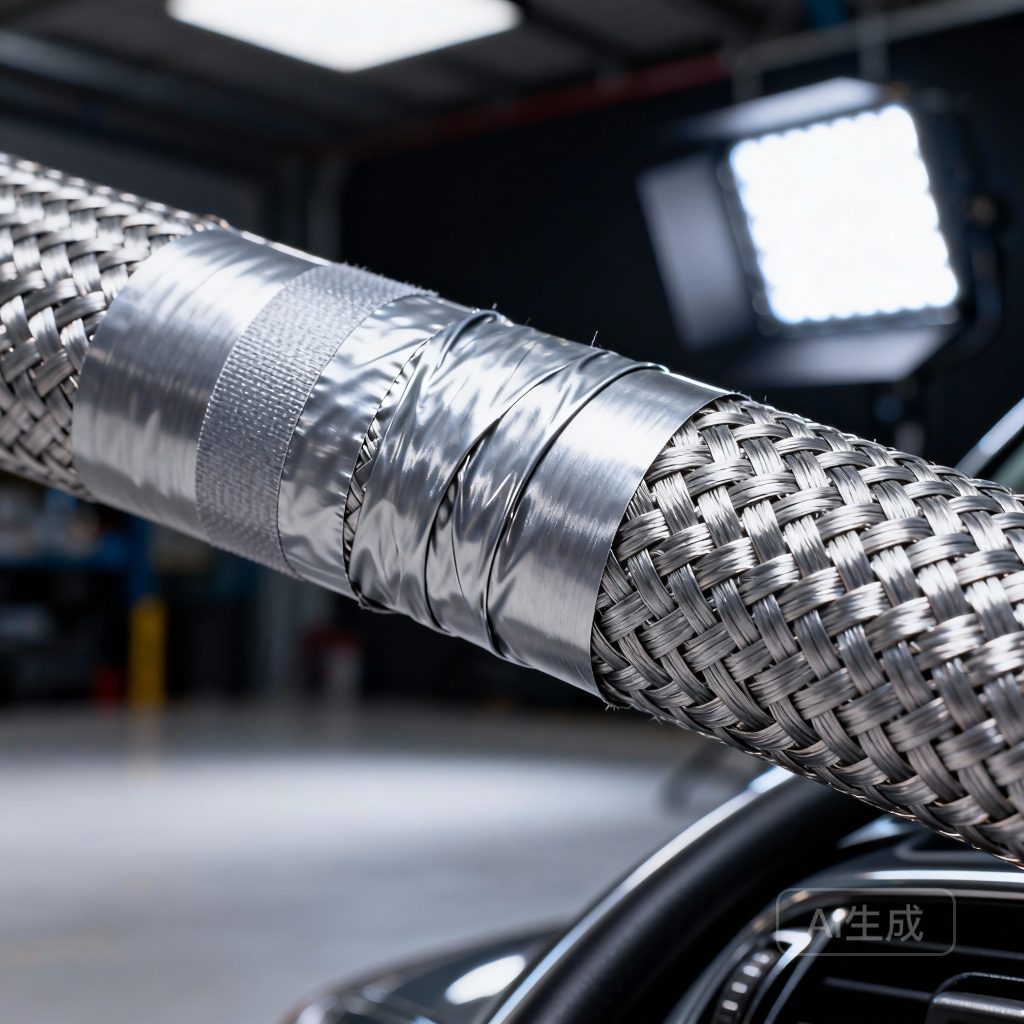

HD1532-0.7-31

The shift to electric vehicles (EVs) and hybrid systems has elevated requirements for connectors. High-voltage (HV) systems, battery management systems (BMS), and thermal management components demand connectors that can withstand extreme temperatures (up to 125°C) and high currents (often exceeding 100A). The HD1532-0.7-31, as a pin socket, is engineered to handle these stresses through robust metal plating (e.g., gold or tin) and reinforced contact design, ensuring minimal resistance and long-term durability in harsh environments.

2. Intelligence: Enabling ADAS and Autonomous Driving

Advanced Driver-Assistance Systems (ADAS), LiDAR, and camera modules rely on high-speed data transfer (e.g., CAN FD, Ethernet) and precise sensor communication. The HD1532-0.7-31’s compact form factor (noted by the “0.7” in its model number, likely indicating a 0.7mm pitch or wire gauge) supports dense, space-efficient wiring harnesses, critical for integrating multiple sensors into limited engine bays or underbody areas. This design is ideal for 通用车型连接器 (general vehicle connectors) where flexibility and adaptability are paramount.

3. Lightweighting: Optimizing for Fuel Efficiency and Range

Automakers are prioritizing lightweight materials to reduce energy consumption and extend EV range. The HD1532-0.7-31’s small size and low-profile construction minimize weight while maintaining structural integrity, making it a top choice for OEMs and aftermarket suppliers seeking to optimize vehicle weight without compromising performance. Its compatibility with a wide range of wire sizes (0.7mm² to 1.5mm², typical for general-purpose vehicles) further enhances its versatility.

4. Reliability: Withstanding the Toughest Conditions

Vehicle connectors must endure vibrations (up to 10g), moisture, and road salt exposure. The HD1532-0.7-31 features a self-locking pin mechanism and strain relief design, reducing the risk of loose connections—a common failure point in traditional connectors. This reliability is why it’s trusted in 汽车电子连接器 (automotive electrical connectors) for safety-critical systems like airbags and powertrain control units.

Conclusion

As the automotive industry evolves, connectors like the HD1532-0.7-31 are at the forefront of innovation. By addressing the need for high-voltage resilience, data efficiency, and space optimization, this pin socket exemplifies how specialized components can drive vehicle performance and safety. For engineers, suppliers, or buyers seeking a universal solution for general-purpose vehicles, the HD1532-0.7-31 stands out as a testament to precision engineering and adaptability in a rapidly changing market.