The automotive industry is undergoing a transformative era, driven by electrification, autonomous driving, and advanced infotainment systems. At the heart of this evolution lies the critical component of vehicle connectivity: automotive connectors. Among these, 6Pin connectors like the DJ7067A-3.5/6.3-21 are emerging as key enablers, adapting to industry demands for efficiency, durability, and miniaturization. This article explores the latest trends reshaping the automotive connector landscape and how 6Pin solutions are positioning themselves as indispensable assets.

### Key Trends Shaping the Automotive Connector Industry

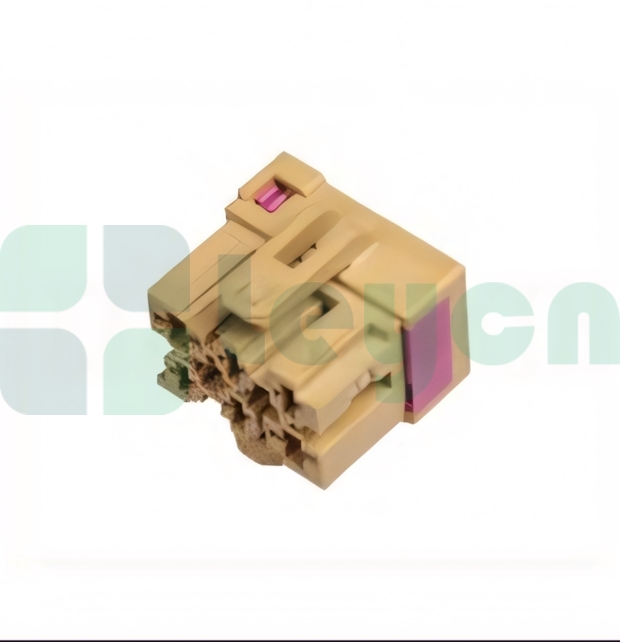

DJ7067A-3.5/6.3-21

#### 1. Electrification of Vehicles: Powering EV and Hybrid Systems

As electric vehicles (EVs) and hybrid electric vehicles (HEVs) dominate market growth, the need for robust connectors that handle high-voltage, high-current applications has surged. Traditional 12V systems are being replaced by 48V and even 800V architectures, demanding connectors that resist heat, corrosion, and mechanical stress. The DJ7067A-3.5/6.3-21, a 6Pin connector, is engineered to meet these demands with its compact design and compatibility across EV powertrains, battery management systems, and charging infrastructure.

#### 2. Miniaturization and High-Density Integration

Modern vehicles are packed with electronic components, from ADAS sensors to infotainment displays, necessitating smaller, space-efficient connectors. 6Pin connectors like the DJ7067A-3.5/6.3-21 excel here, offering precise terminal spacing (3.5/6.3mm) that allows integration into tight wiring harnesses without compromising performance. This miniaturization trend reduces vehicle weight, lowers production costs, and paves the way for more compact, aerodynamic designs.

#### 3. Smart Connectivity and IoT Integration

Connected cars rely on real-time data transfer for ADAS, telematics, and over-the-air updates. Connectors must now support high-speed communication protocols (e.g., CAN FD, Ethernet) while maintaining signal integrity. The DJ7067A-3.5/6.3-21’s robust construction ensures reliable data flow between sensors, ECUs, and infotainment units, making it a cornerstone of the connected vehicle ecosystem.

#### 4. Durability and Environmental Resilience

Automotive connectors face extreme conditions: temperature fluctuations, moisture, and vibration. The DJ7067A-3.5/6.3-21 is engineered with IP67-rated sealing, anti-vibration terminals, and corrosion-resistant materials to withstand these challenges. This durability is critical for OEMs building vehicles for global markets, where reliability directly impacts safety and customer trust.

#### 5. Sustainability and Regulatory Compliance

Eco-conscious manufacturing and recyclable materials are becoming industry standards. Leading automotive connector manufacturers are adopting lead-free solders, recycled plastics, and RoHS-compliant components. The DJ7067A-3.5/6.3-21 aligns with these trends, reducing environmental impact while meeting stringent regulatory requirements.

### Why 6Pin Connectors Matter in 2024

For engineers and buyers, 6Pin connectors like the DJ7067A-3.5/6.3-21 offer a balance of versatility and reliability. Their 6-pin configuration is ideal for mid-range applications—from lighting systems to auxiliary electronics—making them a universal choice across vehicle models. Compatibility with automotive wiring harness systems further simplifies integration, reducing design time and costs.

### Conclusion

As the automotive industry accelerates toward electrification and智能化, 6Pin connectors will remain pivotal. The DJ7067A-3.5/6.3-21 exemplifies how innovation in connector design can power next-generation vehicles. By prioritizing trends like miniaturization, durability, and sustainability, automotive connector manufacturers ensure their products are not just components but enablers of the industry’s future.