In the dynamic landscape of the automotive industry, the role of automotive wire harness connectors is pivotal for ensuring seamless electrical connectivity across vehicle systems. Among the standout solutions is the XF18122-1.2/3.5-21, a 12Pin universal vehicle connector designed to meet the evolving demands of modern automobiles. Let’s explore the core advantages that make this 12 pin connector a top choice for OEMs, repair shops, and automotive enthusiasts alike.

1. Universal Vehicle Adaptability: One Connector, Multiple Applications

The XF18122-1.2/3.5-21 excels in universal vehicle connector compatibility. Engineered as a 12 pin connector for universal vehicle models, it seamlessly integrates with both traditional internal – combustion engine vehicles and emerging new – energy vehicles (NEVs), including electric vehicles (EVs) and hybrid electric vehicles (HEVs). This broad adaptability eliminates the need for developing multiple connector variants for different vehicle models, reducing R&D costs for automakers and simplifying after – sales maintenance. For repair shops, having a single automotive wire harness connector that works across diverse vehicle types means faster service and reduced inventory complexity.

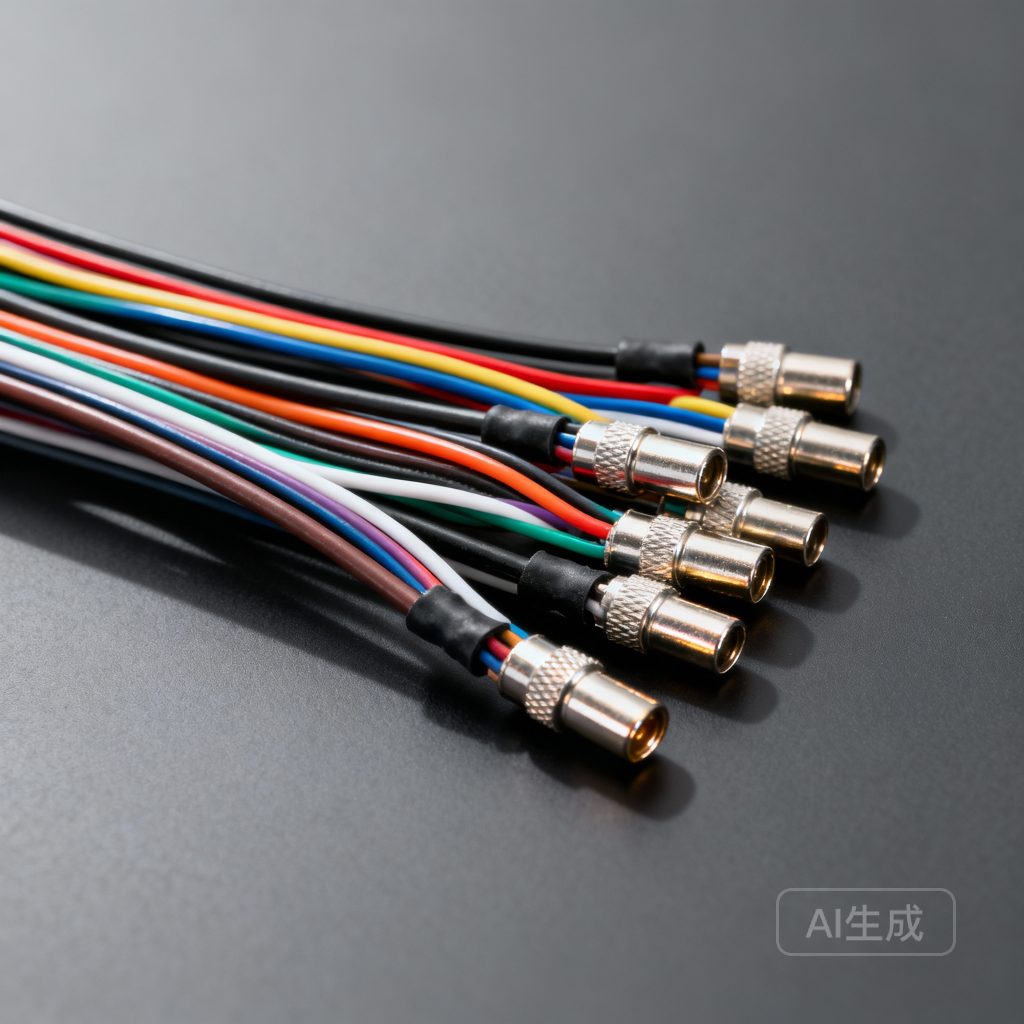

XF18122-1.2/3.5-21

2. Superior Electrical Performance for Stable Connectivity

The 12 – pin design of the XF18122-1.2/3.5-21 isn’t just about quantity; it’s about quality in electrical transmission. Each pin is optimized for low – loss, anti – interference signal and power transfer, even when multiple circuits operate simultaneously. In modern vehicles, where systems like in – car entertainment, advanced driver – assistance systems (ADAS), and safety sensors rely on precise signal transmission, this connector’s wire harness technology ensures minimal signal degradation. Whether it’s transmitting high – definition video for a dashboard display or critical data from a collision sensor, the XF18122-1.2/3.5-21 delivers consistent performance, reducing the risk of system malfunctions and enhancing vehicle safety and user experience.

3. Robust Durability for Harsh Environments

Automotive environments are unforgiving—extreme temperatures, moisture, vibration, and corrosive substances (like road salt) are constant challenges. The 12 pin connector is built with high – grade materials that resist corrosion, withstand temperature fluctuations (from – 40°C to 125°C, for example), and maintain mechanical integrity under vibration. Its durable construction ensures reliable performance even in the engine bay’s high – heat, high – vibration zone or in cold, humid climates. With a high cycle life (thousands of plug – and – play operations without wear – related failures), this connector outlasts many competitors, reducing maintenance frequency and total cost of ownership for vehicle owners and fleets.

4. User – Centric Design for Easy Installation & Maintenance

Installation and maintenance efficiency are crucial in automotive manufacturing and repair. The XF18122-1.2/3.5-21 features an ergonomic design that enables smooth, tool – free plug – and – play operations in most cases. Technicians can quickly install or replace the connector, minimizing downtime during production or repairs. The clear pin – out labeling and intuitive locking mechanism also reduce the risk of misconnection, a common source of electrical issues. For DIY enthusiasts or small repair shops, this ease of use translates to faster service, lower labor costs, and a better customer experience.

In conclusion, the XF18122-1.2/3.5-21 12Pin automotive wire harness connector stands out with its universal compatibility, superior electrical performance, rugged durability, and user – friendly design. As the automotive industry shifts toward electrification and smart mobility, connectors like this will play an increasingly vital role in ensuring vehicles are efficient, safe, and reliable. Whether you’re an automaker, a repair professional, or a vehicle owner, choosing a high – quality connector like the XF18122-1.2/3.5-21 is a strategic decision to future – proof your automotive electrical systems.