The automotive industry is rapidly evolving with advancements in electrification, ADAS, and connectivity, driving the demand for more robust and versatile automotive wiring harness connectors. At the heart of this evolution lies the DJ7152A-3.5-21, a 15Pin connector designed to meet the needs of universal vehicle applications. This article explores why this connector has become a preferred choice for OEMs and aftermarket suppliers alike.

1. 15Pin Design: Versatility Meets Efficiency

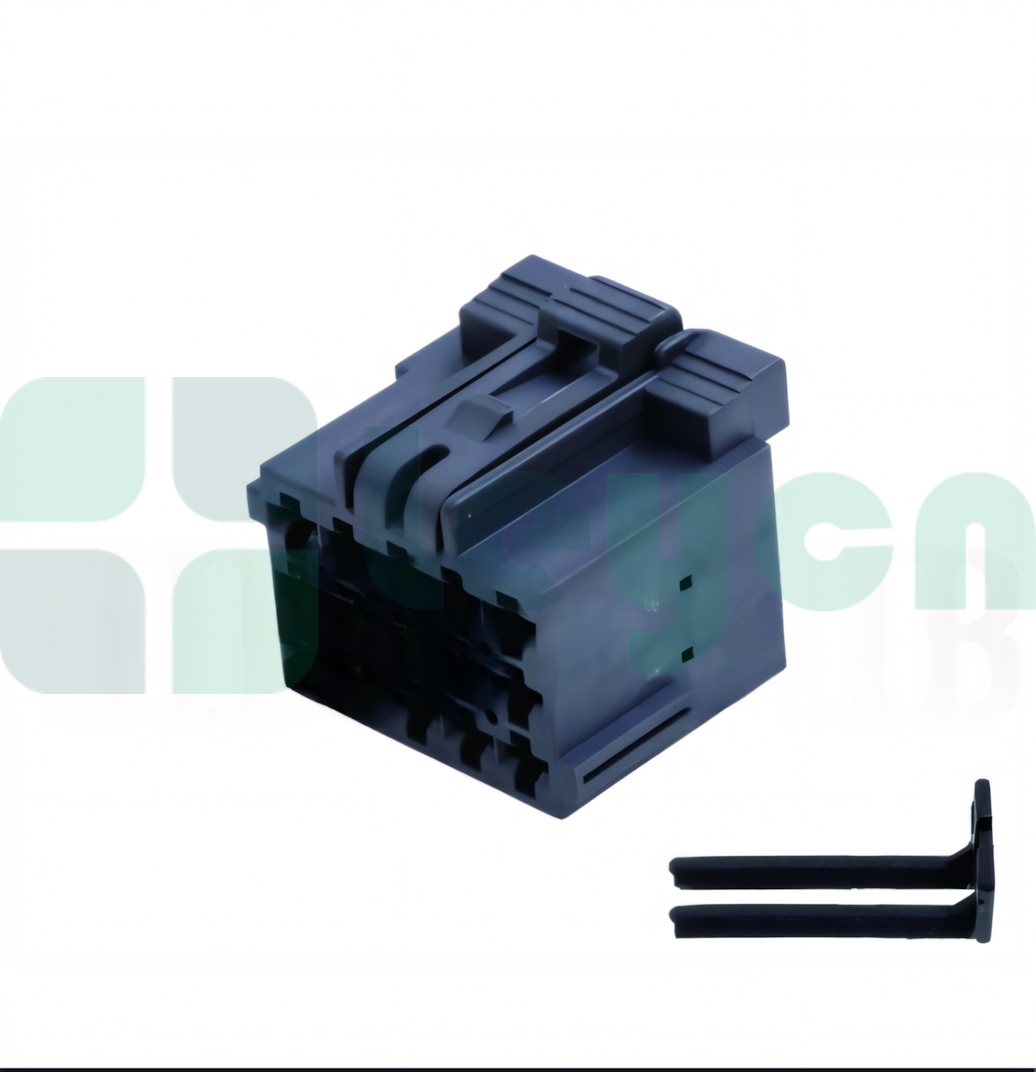

The DJ7152A-3.5-21 features a 15Pin configuration that balances functionality and space efficiency. This design supports multiple signal types simultaneously, including power, CAN bus communication, sensor data, and audio/video feeds—critical for modern vehicle systems like infotainment, ADAS, and engine control units (ECUs). Unlike single-purpose connectors, its 15Pin layout eliminates the need for complex multi-harness setups, streamlining wiring and reducing installation time.

DJ7152A-3.5-21

2. 3.5mm Pitch: Precision Engineering for High-Density Connectivity

The 3.5mm pitch (distance between pins) is a key technical advantage, enabling high-density wiring in tight engine bays and under-dash spaces. This compact design minimizes contact resistance and signal interference, ensuring stable performance even with high-speed data protocols like CAN FD or Ethernet. For automotive engineers, the precision of the 3.5mm pitch translates to fewer failures and easier diagnostic maintenance.

3. Universal Vehicle Compatibility: A Cost-Effective Solution

Engineered for universal vehicle applications, the DJ7152A-3.5-21 eliminates the need for custom connectors across different OEM models or vehicle generations. This universality reduces inventory costs, shortens lead times, and simplifies procurement for manufacturers producing multi-platform vehicles. Whether retrofitting older models or upgrading new ones, this connector offers a plug-and-play experience without compromising quality.

4. Robust Construction for Harsh Environments

Automotive environments demand durability, and the DJ7152A-3.5-21 delivers with high-temperature-resistant plastics and corrosion-resistant metal contacts. It withstands extreme temperatures (-40°C to 125°C), vibrations, and moisture, making it suitable for engine compartments, undercarriages, and exposed exterior harnesses. Compliance with IP67/IP6K9K ratings further ensures protection against dust and water ingress.

5. Quality Assurance and Industry Compliance

Backed by ISO 9001 and IATF 16949 certifications, the DJ7152A-3.5-21 undergoes rigorous testing for electrical performance, durability, and environmental resilience. This ensures consistent quality across production runs, meeting the stringent safety standards required for automotive systems. For suppliers and OEMs, this compliance minimizes risks and accelerates product certification.

Conclusion

As the automotive industry shifts toward electric and autonomous vehicles, the DJ7152A-3.5-21 remains a cornerstone of reliable automotive connector solutions. Its 15Pin design, precision engineering, and universal compatibility make it an ideal choice for both OEMs and aftermarket applications. For anyone seeking a cost-effective, durable connector for universal vehicle wiring needs, the DJ7152A-3.5-21 is a proven solution.