Introduction

Automotive electrical systems rely on robust, reliable connectors to ensure seamless power transmission and data flow between components. Among these, the DJ7015-6.3-21 1Pin Connector stands out as a versatile solution for general-purpose vehicle applications. As a single-pin (1Pin) connector, it simplifies wiring harness design while meeting the demands of modern automotive engineering. In this article, we explore why this connector has become a preferred choice for OEMs and aftermarket suppliers worldwide.

1. Universal Compatibility for Diverse Vehicle Models

The DJ7015-6.3-21 is engineered for general-purpose vehicle applications, meaning it integrates seamlessly with a wide range of makes and models. Whether installed in passenger cars, light commercial vehicles, or even certain SUVs, its standardized design ensures compatibility across different electrical architectures. This universality reduces inventory complexity for manufacturers and simplifies repairs for automotive technicians, who can often use the same connector across multiple vehicle lines.

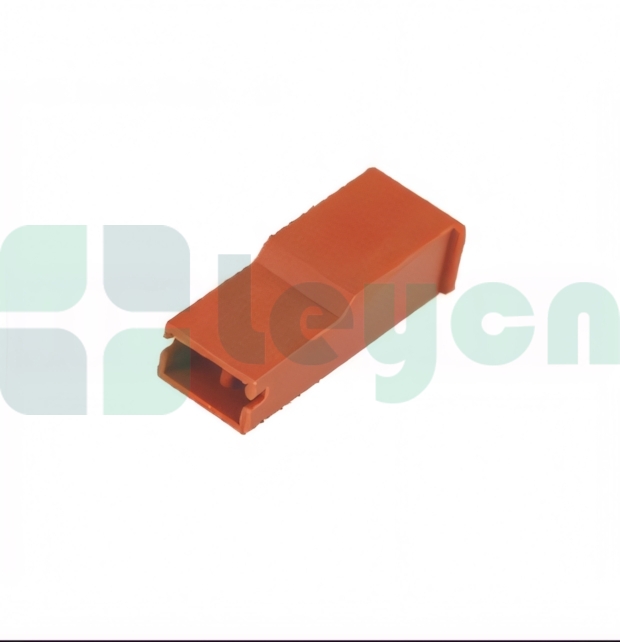

DJ7015-6.3-21

2. Robust Construction for Harsh Environments

Automotive connectors must withstand extreme conditions, from engine bay temperatures exceeding 120°C to exposure to moisture, dust, and vibration. The DJ7015-6.3-21 addresses these challenges with a durable metal shell and high-grade PA66 nylon housing, both tested to meet automotive industry standards like ISO 16949. Its robust terminal design minimizes contact resistance and prevents corrosion, ensuring long-term reliability even in the most demanding environments.

3. Reliable Electrical Performance

For electrical systems, stability is critical. The 1Pin design of the DJ7015-6.3-21 ensures a secure, low-resistance connection for single-wire applications, such as powering auxiliary lights, sensors, or small electrical accessories. Its precision-molded contacts maintain consistent contact pressure, reducing the risk of signal loss or short circuits—a vital feature for vehicle safety and performance.

4. Cost-Effective Design for Mass-Production

Automotive manufacturers prioritize cost efficiency without compromising quality. The DJ7015-6.3-21 achieves this through its simplified 1Pin architecture, which reduces material costs and assembly time. By standardizing on this connector, OEMs can lower production overheads, while aftermarket suppliers benefit from competitive pricing for replacement units. This makes it an economical choice for both original equipment and post-purchase maintenance.

5. Easy Installation and Maintenance

Designed with practicality in mind, the DJ7015-6.3-21 features a user-friendly crimp-and-lock mechanism, enabling quick and secure wiring. Technicians can install or replace it without specialized tools, saving time during vehicle assembly or repairs. Its compact size also allows for integration into tight engine bay spaces, where larger connectors might obstruct other components.

Conclusion

The DJ7015-6.3-21 1Pin automotive connector excels in general-purpose vehicle applications by combining universal compatibility, rugged durability, reliable performance, and cost-effectiveness. As automotive technology evolves toward electrification and智能化, connectors like this remain foundational to ensuring electrical systems operate efficiently. For anyone seeking a dependable 1Pin solution, the DJ7015-6.3-21 is a testament to engineering excellence in automotive connectivity.