The automotive industry is undergoing a seismic shift with the rise of electric vehicles (EVs), autonomous driving, and smart connectivity. This evolution demands advanced automotive wire harness connector solutions that balance reliability, versatility, and technological innovation. Among these, the DJ7036A-2.2-21 3Pin automotive wire harness connector stands out as a game-changer for universal vehicle applications, addressing the needs of both OEMs and aftermarket segments.

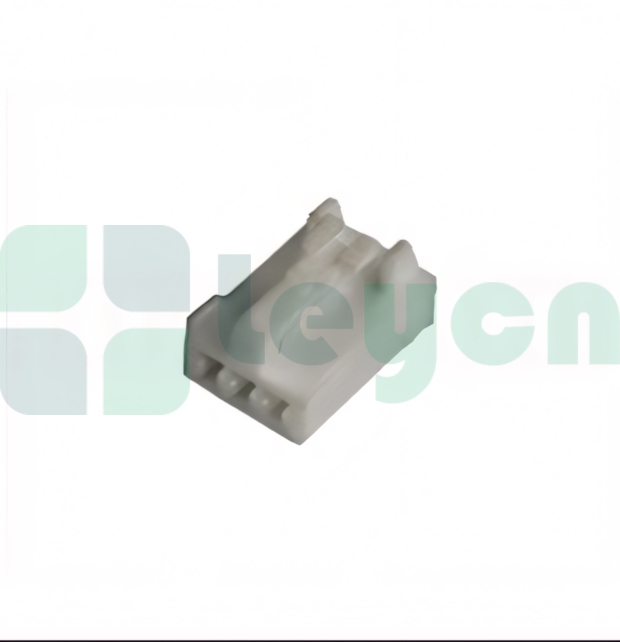

Product Spotlight: DJ7036A-2.2-21 3Pin Connector

The DJ7036A-2.2-21 is a 3Pin automotive wire harness connector engineered for universal vehicle compatibility. Its core strength lies in a design that eliminates the need for vehicle-specific connectors, reducing inventory complexity for manufacturers and streamlining repair processes for technicians. The 3Pin configuration ensures stable electrical transmission for critical systems (e.g., lighting, sensor networks, auxiliary power), while its robust construction—featuring corrosion-resistant terminals and heat-resistant insulation—meets the harsh operating conditions of modern automobiles (vibration, temperature fluctuations, and moisture exposure).

DJ7036A-2.2-21

Industry Trends Driving Demand for Universal Connectors

As EVs and hybrid vehicles dominate market growth, the demand for wire harness technology has surged. These vehicles require higher current-carrying capacity and EMI (electromagnetic interference) resistance, making connectors like the DJ7036A-2.2-21 essential. Additionally, the rise of software-defined vehicles (SDVs) and over-the-air (OTA) updates has increased the complexity of in-vehicle electrical architectures. Universal connectors offer a cost-effective, future-proof solution, as they adapt to evolving vehicle platforms without redesigns.

Technological Innovation in Connector Design

Modern automotive wire harness connector design integrates innovations like:

– Material Science: High-performance polymers and gold-plated terminals enhance durability and conductivity.

– Ergonomic Engineering: Tool-free assembly and color-coded pins (for 3Pin models like DJ7036A-2.2-21) reduce installation errors.

– Sealing Technologies: IP67-rated waterproofing for applications in EV battery management systems (BMS) or ADAS (Advanced Driver-Assistance Systems) sensors.

Practical Applications & User Benefits

For OEMs, the DJ7036A-2.2-21 cuts production costs by standardizing connector inventory across multiple vehicle lines (e.g., sedans, SUVs, light commercial vehicles). In the aftermarket, it simplifies repairs—technicians can quickly source a single connector for diverse makes/models, minimizing vehicle downtime. Real-world case studies show that fleets using universal connectors reduce maintenance costs by 15–20% due to faster part availability and reduced SKU (stock-keeping unit) complexity.

Choosing the Right Connector: Key Considerations

When selecting a 3Pin connector like the DJ7036A-2.2-21, prioritize:

1. Compatibility: Verify universal fitment for your vehicle type (passenger, commercial, EV).

2. Certifications: Look for ISO/TS 16949 (automotive quality) and UL (safety) compliance.

3. Environmental Resistance: Ensure ratings for temperature (-40°C to +125°C typical), vibration, and moisture.

4. Manufacturer Reputation: Partner with brands known for reliability in automotive connectivity solutions.

In conclusion, the DJ7036A-2.2-21 exemplifies how automotive wire harness connector design is evolving to meet industry demands for versatility, durability, and cost efficiency. As vehicles become more electrified and connected, solutions like this 3Pin universal connector will remain pivotal in powering the next generation of automotive innovation.