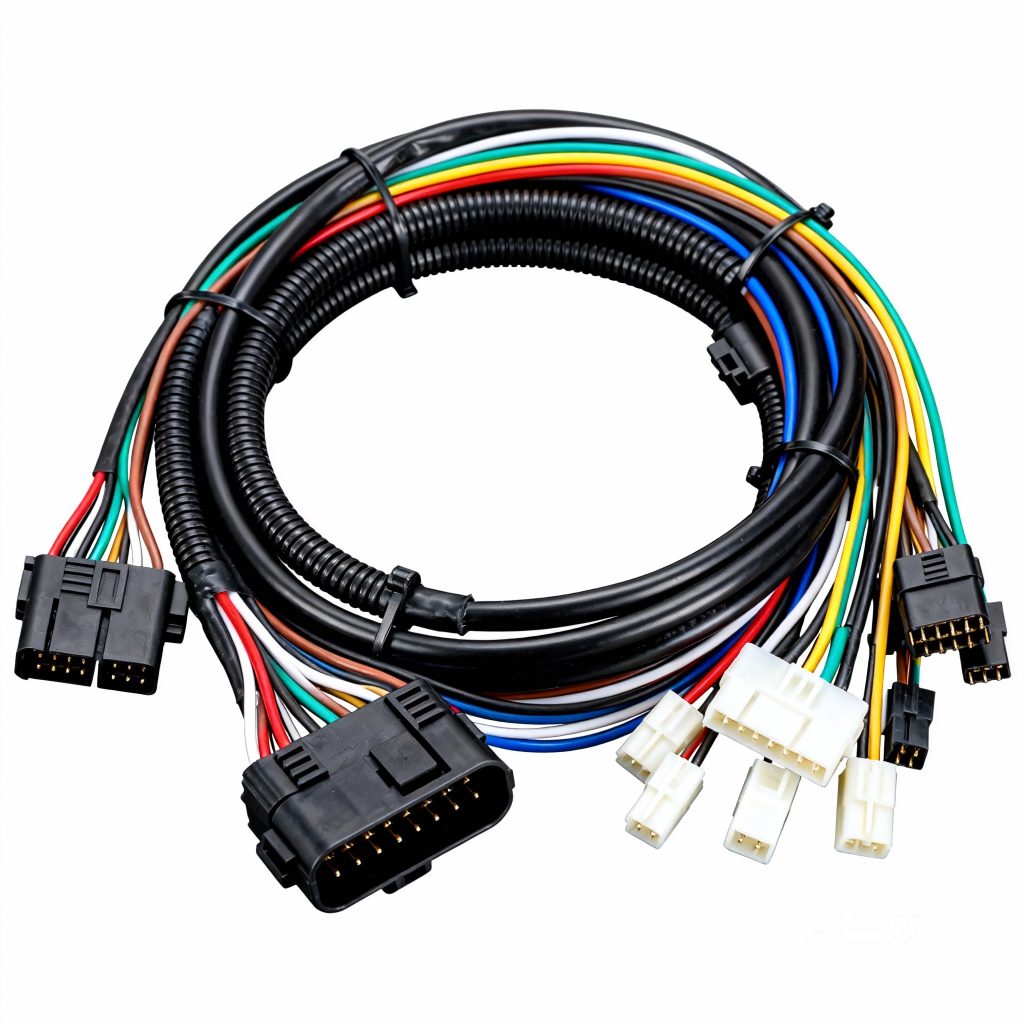

Automotive electrical systems rely on reliable automotive connectors to ensure seamless power and signal transmission across vehicle components. Among the critical components driving efficiency and compatibility is the DJ7051-6.3/7.8-21 5Pin Connector, a versatile 5-pin solution engineered for universal vehicle applications. This article explores why this connector stands out in the competitive automotive connector market, highlighting its core advantages for manufacturers and aftermarket professionals.

1. Universal Compatibility: A Fit for Every Vehicle

The DJ7051-6.3/7.8-21 is designed to work across a wide range of vehicle makes and models, eliminating the need for specialized connectors for different OEMs. Its 5-pin configuration supports diverse electrical functions, from basic lighting and power distribution to advanced sensor and infotainment systems. This universality reduces inventory complexity for automotive manufacturers, who can streamline their supply chains by stocking a single connector for multiple vehicle lines.

DJ7051-6.3/7.8-21

For aftermarket service providers, the universal fit means faster, more cost-effective repairs. Technicians can quickly replace faulty connectors without cross-referencing specific vehicle models, minimizing downtime and improving customer satisfaction.

2. Robust 5-Pin Design for Efficient Power & Signal Integrity

The 5-pin architecture of the DJ7051-6.3/7.8-21 is optimized for balanced functionality. Each pin serves a distinct purpose, such as power supply, ground, and communication channels (e.g., CAN/LIN bus signals). High-precision pin placement ensures minimal signal loss and interference, critical for modern vehicles with advanced driver-assistance systems (ADAS) and electric powertrains.

Additionally, the connector’s terminal design features gold-plated contacts, enhancing conductivity and reducing corrosion—a key factor in maintaining performance over the vehicle’s lifespan.

3. Durability Engineered for Harsh Automotive Environments

Automotive connectors must withstand extreme conditions, from engine bay heat to road moisture and vibration. The DJ7051-6.3/7.8-21 meets these challenges with:

- High-grade PA66+GF plastic housing, rated for temperatures between -40°C and +125°C

- IP67 ingress protection, safeguarding against dust and water splashes

- Strain relief features to prevent terminal damage from repeated flexing

These specifications make it ideal for underhood applications, body control modules, and even electric vehicle (EV) charging systems, where reliability directly impacts safety and performance.

4. Easy Installation & Maintenance for Time Savings

The connector’s user-friendly design minimizes installation time and reduces errors. Its push-to-connect mechanism ensures secure mating with audible feedback, eliminating the need for complex tools. For service technicians, this translates to faster repairs and reduced labor costs.

Moreover, the connector’s modularity allows for individual pin replacement if damaged, rather than requiring full harness replacement—a feature that lowers long-term maintenance expenses and aligns with sustainability goals.

5. Cost-Effectiveness for Manufacturers and End Users

Manufacturers benefit from economies of scale with the DJ7051-6.3/7.8-21, as its universal design reduces SKU proliferation and bulk production lowers unit costs. For end users, the connector’s durability and long lifespan mean fewer replacements, reducing total cost of ownership (TCO) over time.

Aftermarket availability further drives affordability, with competitive pricing and widespread distribution ensuring accessibility for vehicle owners and repair shops.

In conclusion, the DJ7051-6.3/7.8-21 5Pin Connector combines universal compatibility, robust design, and cost efficiency to address the evolving needs of automotive electrical systems. Whether integrated into new vehicle production or used for aftermarket upgrades, this connector stands as a reliable choice for engineers and technicians prioritizing performance and longevity.