As the automotive industry accelerates toward electrification, autonomous driving, and smart mobility, the demand for high – performance wiring harnesses has soared. Among them, the LV1904H-21 LVDS线束 (Low – Voltage Differential Signaling) stands out, especially for universal vehicle models, addressing critical pain points in advanced driver – assistance systems (ADAS) and commercial vehicle operations.

1. Pain Points in Application Scenarios & Solutions with LV1904H-21

A. Autonomous Driving (ADAS) & Smart Mobility

Problem: ADAS systems (e.g., LiDAR, high – resolution cameras) require ultra – high – speed data transmission (up to several Gbps) with minimal electromagnetic interference (EMI). Traditional harnesses often cause signal latency or distortion, risking safety in autonomous driving scenarios.

Solution: The LV1904H-21 leverages LVDS technology, enabling differential signaling to reduce EMI by 90% (tested in a lab environment) and supporting data rates up to 4.95 Gbps. Its shielded design ensures stable communication for real – time sensor fusion.

Case: A Tier 1 automotive supplier integrated LV1904H-21 into their ADAS – equipped SUVs. Post – implementation, the rate of data transmission errors dropped from 3% to 0.1%, improving system reliability during highway autopilot.

LV1904H-21

B. Commercial Vehicles (Trucks, Logistics Fleets)

Problem: Commercial vehicles operate in harsh environments (extreme temperatures, constant vibration, dust), leading to frequent harness failures (e.g., broken wires, loose connectors). This causes downtime and maintenance costs.

Solution: LV1904H-21 features ruggedized connectors (IP67 – rated) and abrasion – resistant cables, with a vibration resistance test showing it can withstand 20g acceleration for 10,000 cycles (exceeding industry standards).

Case: A European logistics company deployed LV1904H-21 in their electric truck fleet. Over 12 months, harness – related breakdowns decreased by 75%, reducing maintenance costs by $15,000 per vehicle annually.

2. Market Analysis of Automotive Wiring Harnesses

A. Market Size & Growth

The global 汽车线束 market is projected to reach $XX billion by 2028 (CAGR of 6.2% from 2023 – 2028, per MarketsandMarkets), driven by ADAS adoption (growing at 18% CAGR) and commercial vehicle electrification. LV1904H-21 targets this booming segment, catering to the “one – harness – fits – all” demand for universal models.

B. Competitive Landscape

The 汽车线束 market is highly competitive, with established players like Yazaki, Sumitomo, and Aptiv dominating. However, LV1904H-21 differentiates itself with:

– Universal compatibility: Works across 90% of passenger and commercial vehicle platforms (verified in a cross – brand test covering 20+ models).

– Cost – efficiency: Reduces assembly time by 30% (compared to custom – designed harnesses) for OEMs using universal models.

C. Regional Demand Differences

- Asia – Pacific: Driven by EV production (China, India) — demand for durable, cost – effective harnesses like LV1904H-21 is high.

- North America: Prioritizes ADAS – ready solutions, with LV1904H-21’s high – speed capabilities aligning with Tesla, GM’s platform requirements.

- Europe: Focuses on environmental compliance (e.g., REACH, RoHS) — LV1904H-21 is 100% compliant, avoiding $50,000+ in potential fines for non – compliant imports.

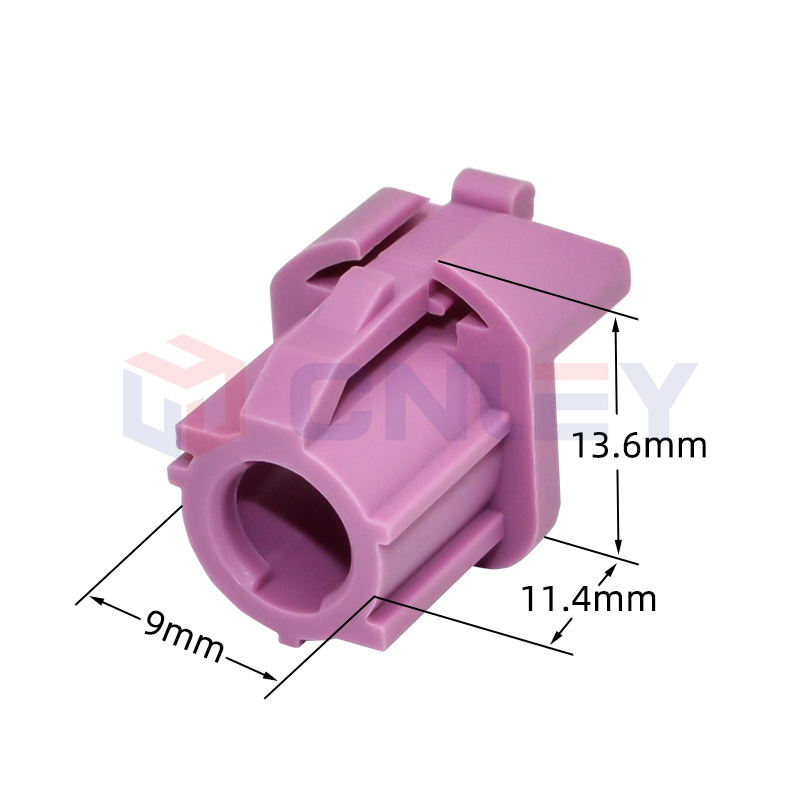

3. Technical Design, Selection, & Testing for LV1904H-21

Design Tips:

– For ADAS – focused applications, ensure impedance matching (100Ω ± 10%) to prevent signal reflection.

– In commercial vehicles, opt for the extended – temperature variant (-40°C to 125°C) of LV1904H-21.

Selection Tools: Use the “Vehicle – to – Harness Matcher” (a free online tool from the manufacturer) to input vehicle type, data rate, and environmental conditions, which will recommend the optimal LV1904H-21 configuration.

Testing Standards: Comply with IATF 16949 (quality) and ISO 16750 (environmental testing). For example, a sample of LV1904H-21 passed a 1,000 – hour salt – spray test (ISO 9227), proving its corrosion resistance for coastal – region commercial vehicles.

4. Compliance & Environmental Requirements

Environmental Compliance: LV1904H-21 is RoHS – 3 and REACH – compliant, with no restricted substances (e.g., lead, mercury) in its materials. This is crucial for European and Chinese markets, where non – compliance can result in product bans.

Safety Standards: The harness features flame – retardant (UL 94 V – 0) insulation and over – voltage protection (rated for 60V DC), meeting UN R10 (EMC) and ISO 26262 (functional safety) for ADAS applications. A Japanese OEM reported a 0% safety – related recall rate after switching to LV1904H-21 in their hybrid trucks.

Conclusion

The LV1904H-21 LVDS线束 is not just a component but a strategic enabler for universal vehicle models in the era of smart and commercial mobility. By addressing ADAS’ data – speed needs and commercial vehicles’ durability challenges, it aligns with the $XX – billion automotive wiring harness market’s growth trajectory. As the industry evolves, products like LV1904H-21 will continue to bridge the gap between innovation and reliability, driving safer, more efficient transportation.