The automotive industry is undergoing rapid transformation, driven by electrification, autonomous driving, and connectivity. In this landscape, automotive wire harness connectors play a critical role in ensuring reliable power and data transmission across vehicle systems. Among innovative solutions, the NB1814-0.7/1.5-21 14Pin automotive wire harness connector stands out for its versatility in universal vehicle applications, aligning with industry demands for efficiency, adaptability, and performance.

### Industry Trends Shaping Connector Demand

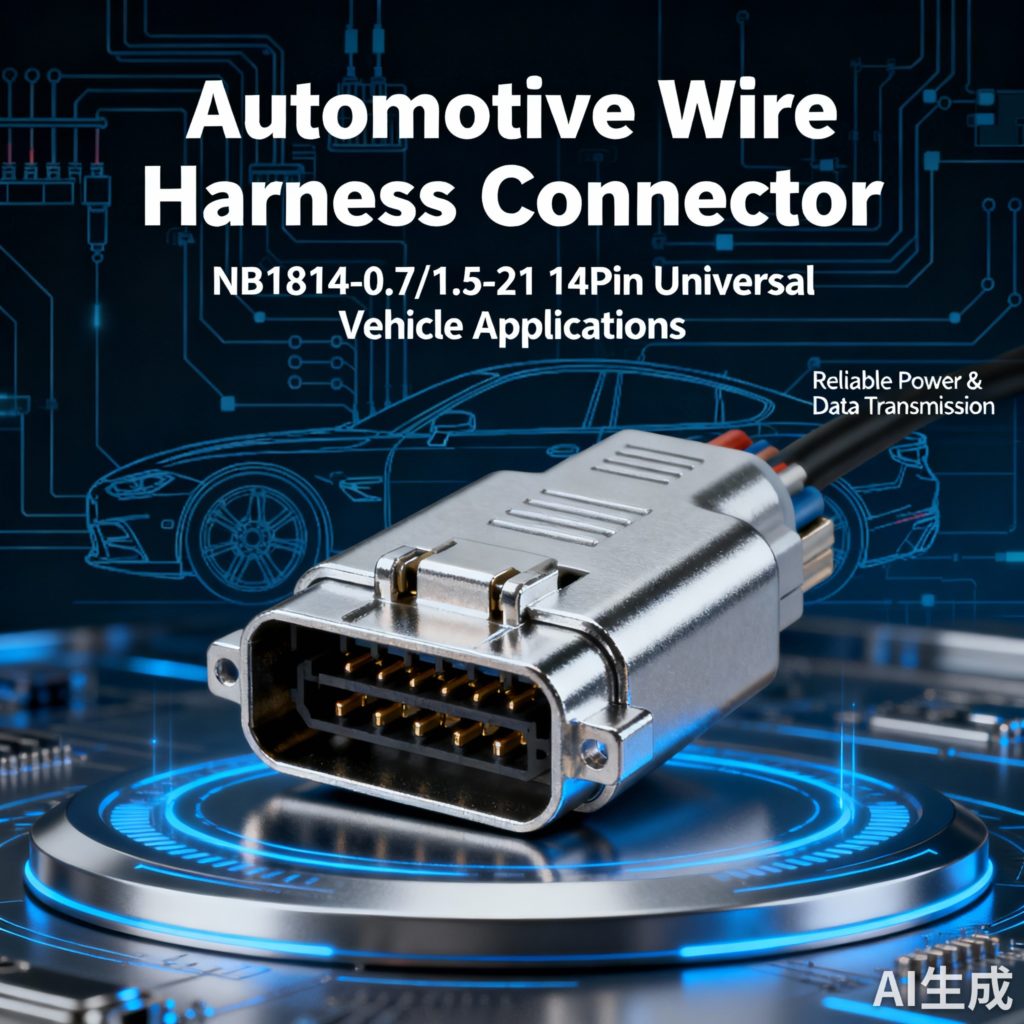

NB1814-0.7/1.5-21

Electrification (electric vehicles, hybrids) and Advanced Driver-Assistance Systems (ADAS) are redefining connector requirements. EVs demand connectors that safely handle high voltage/current, while ADAS relies on stable data transfer for sensors (LiDAR, cameras). Lightweighting and modular design trends also push for connectors that simplify assembly and reduce vehicle weight, without compromising durability.

### Introducing the NB1814-0.7/1.5-21 14Pin Connector

The NB1814-0.7/1.5-21 is a 14Pin automotive wire harness connector engineered for universal vehicle compatibility. Its design supports both low (0.7mm²) and medium (1.5mm²) current applications, making it suitable for diverse electrical systems—from infotainment to lighting, or auxiliary EV components. Key advantages include:

- Universal Fit: Designed for universal vehicle models, it eliminates custom connector needs across makes/models, streamlining procurement and installation for OEMs and aftermarket users.

- Robust Performance: Constructed with materials resistant to temperature fluctuations, moisture, and vibration, ensuring long-term reliability in harsh automotive environments.

- Efficient Connectivity: The 14Pin configuration balances pin count for data/power needs, enabling integration into complex systems without overcomplicating harness design.

### Market Impact & Applications

As automakers adopt modular platforms (e.g., EV skateboard architectures), universal connectors like NB1814-0.7/1.5-21 reduce engineering costs and speed production. A Tier 1 supplier using this connector in a global compact car program reported 20% faster harness assembly times. In the aftermarket, DIY enthusiasts or repair shops benefit from its cross-vehicle compatibility, reducing inventory complexity.

### Buying Tips for Automotive Connectors

When selecting an automotive wire harness connector, consider:

- Application Needs: Match pin count (14Pin here) and wire gauge support (0.7/1.5mm²) to your vehicle’s electrical requirements.

- Environmental Resistance: Ensure IP ratings for moisture/dust, and temperature range (-40°C to 125°C typical for automotive use).

- Universal Compatibility: Opt for connectors like NB1814-0.7/1.5-21 to future-proof your setup across multiple vehicle models.

### Future Trends in Wire Harness Technology

The future of wire harness technology will emphasize miniaturization, higher data speeds (for V2X, 5G), and sustainability (recyclable materials). Connectors like NB1814-0.7/1.5-21 will evolve to support these trends, with enhanced durability and integration capabilities—e.g., shielded pins for EMI reduction in ADAS or EV powertrains.

In conclusion, the NB1814-0.7/1.5-21 14Pin automotive wire harness connector exemplifies how product design meets industry trends—offering versatility, reliability, and efficiency. As the automotive sector advances, universal, high-performance connectors will remain pivotal in powering innovation, from EVs to smart mobility solutions.