The automotive industry relies heavily on reliable electrical connections to ensure vehicle performance, safety, and efficiency. Among these critical components, automotive connector systems play a pivotal role in transmitting power and signals throughout a vehicle’s wiring harness. For automotive professionals seeking a versatile, durable solution, the 6.3H1-2A 1Pin automotive connector stands out as a leading choice for universal vehicle applications. This 1Pin connector, designed for general-fitment models, combines robust engineering with user-friendly features to address the evolving needs of modern automotive manufacturing and repair.

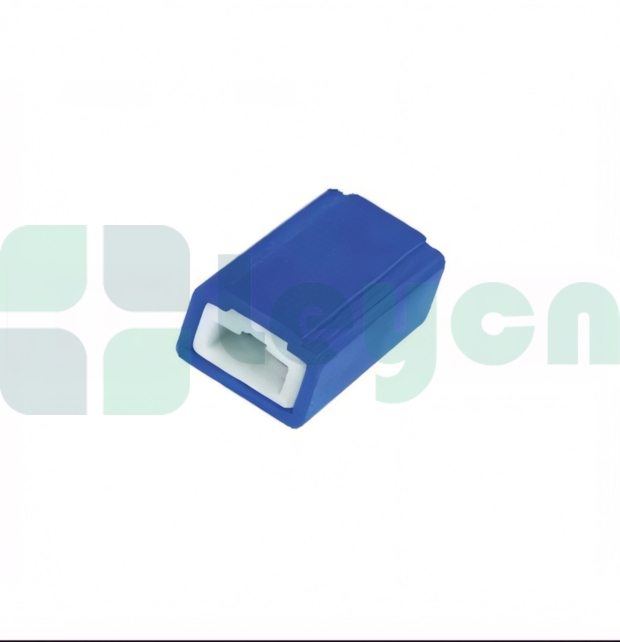

6.3H1-2A

1. Universal Compatibility for Diverse Vehicle Fleets

The 6.3H1-2A is engineered to be a universal fit, making it suitable for a wide range of vehicle models across different makes and years. Unlike specialized connectors tailored to single-model vehicles, this 1Pin connector simplifies inventory management for OEMs and repair shops by reducing the need for multiple SKUs. Whether installed in passenger cars, light trucks, or even hybrid/electric vehicles, its adaptable design ensures seamless integration into existing wiring harnesses without extensive modifications.

2. Durability Engineered for Harsh Automotive Environments

Automotive connectors must withstand extreme conditions, including temperature fluctuations, vibration, moisture, and electrical stress. The 6.3H1-2A excels in this regard, thanks to its high-quality construction:

- Material Quality: Uses corrosion-resistant metal contacts and a rugged, high-impact plastic housing to resist wear and environmental damage.

- Environmental Protection: Meets industry standards for ingress protection (e.g., IP67-rated in typical configurations), safeguarding against dust and water intrusion.

- Vibration Resistance: Its secure locking mechanism ensures stable connections even during high-vibration scenarios, reducing the risk of loose contacts or signal loss.

3. Easy Installation and Maintenance

Time efficiency is crucial in automotive production and repair. The 6.3H1-2A’s 1Pin design streamlines installation:

- Simple Crimping: Requires minimal tooling, allowing technicians to terminate wires quickly with standard crimping equipment.

- Quick Mating: A user-friendly latching system enables fast, error-free connection, reducing downtime during vehicle assembly or repairs.

- Cost-Effective Upgrades: Its universal fit and easy installation lower labor costs, making it an economical choice for retrofits and maintenance.

4. Reliable Electrical Performance

Electrical integrity is non-negotiable in automotive systems. The 6.3H1-2A ensures consistent power transmission with:

- Low Resistance: High-conductivity metal contacts minimize voltage drops, maintaining efficient power delivery.

- High Current Handling: Designed to support typical automotive electrical loads, from small-signal applications to moderate power requirements.

- Long Lifespan: Durable materials and precision engineering extend the connector’s operational life, reducing replacement frequency and long-term costs.

In conclusion, the 6.3H1-2A 1Pin automotive connector is a testament to how thoughtful design can address the dual demands of reliability and versatility in automotive wiring. For automotive manufacturers, fleet operators, and repair services, this universal connector offers a cost-effective, robust solution to ensure electrical systems function optimally across diverse vehicle applications. As the automotive industry continues to evolve toward electrification and智能化 (intelligentization), the 6.3H1-2A remains a foundational component for maintaining safety and performance.